In the fast-paced world of manufacturing, efficiency is paramount. Companies constantly seek ways to optimize their operations and improve productivity, and one of the most effective tools to achieve these goals is the implementation of crane kits. These kits, which include essential components like hoists, tracks, and controls, provide a streamlined solution for lifting and moving heavy materials and equipment within a facility. By integrating crane kits into manufacturing processes, businesses can significantly enhance their efficiency, reduce labor costs, and improve safety standards. One of the primary benefits of crane kits is their ability to automate material handling tasks. In traditional manufacturing environments, workers often rely on manual labor to move heavy objects, which can lead to fatigue, errors, and potential injuries. Crane kits eliminate much of this manual effort by providing a mechanical means to lift and transport materials. This not only saves time but also allows employees to focus on more value-added tasks, ultimately increasing overall productivity. By automating these processes, manufacturers can streamline workflows, reduce cycle times, and accelerate production rates.

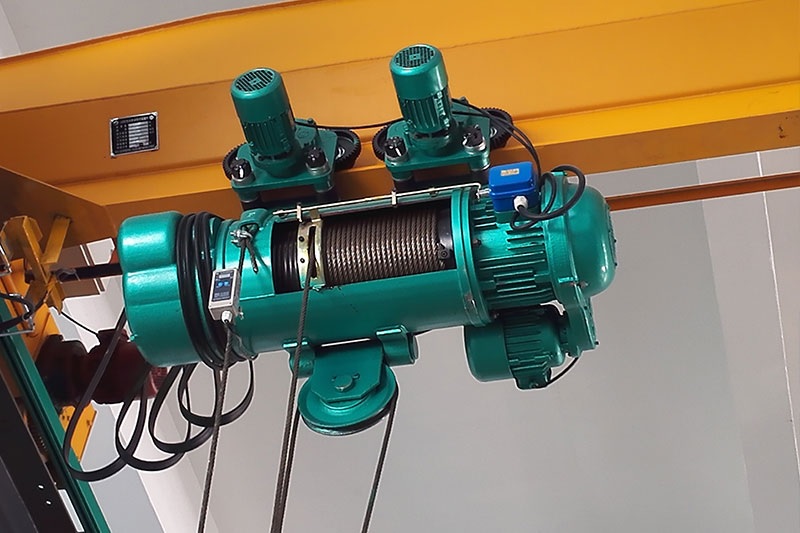

Moreover, crane kits are designed with versatility in mind. They can be customized to suit various manufacturing environments, whether in assembly lines, warehouses, or fabrication shops. This adaptability allows manufacturers to configure their crane systems to meet specific operational needs. For example, a manufacturing facility producing large components may require a bridge crane with a high lifting capacity, while a smaller operation might benefit from a lightweight gantry crane. The flexibility of crane kits means that manufacturers can select the right solution to optimize their unique processes, making it easier to scale operations as demand increases. Safety is another critical aspect where crane kits make a significant impact. The manufacturing sector often poses various hazards, particularly when handling heavy loads. Crane kits are designed with safety features that protect both workers and equipment. For instance, many systems come equipped with overload protection, emergency stop buttons, and safety brakes. By reducing the risks associated with manual lifting, companies can create a safer work environment, resulting in fewer accidents and injuries. This not only safeguards employees but also minimizes the potential for costly downtime due to safety incidents.

Furthermore, the installation of crane kits can lead to improved space utilization within a facility. Traditional material handling methods often require extensive floor space for moving equipment and materials. In contrast, crane systems can be mounted overhead, freeing up valuable floor space for other operations. This optimized layout allows for better organization of materials and can lead to improved workflow and polipasto eléctrico efficiency. In conclusion, crane kits represent a transformative solution for manufacturers aiming to enhance operational efficiency. By automating material handling, offering versatile configurations, prioritizing safety, and optimizing space utilization, these systems empower businesses to break barriers and elevate their manufacturing capabilities. As industries continue to evolve and demand for efficiency increases, the strategic implementation of crane kits will play a vital role in shaping the future of manufacturing, driving innovation, and ensuring competitiveness in an ever-changing marketplace.