The manufacturing of crane kits has seen significant innovations over the years, particularly in the integration of electric hoists. These advancements have transformed the concept of lifting and moving heavy loads, making processes more efficient and safe across various industries. Electric hoists, which use electric power to lift and lower loads, have become integral components in crane kits, allowing for enhanced performance and reliability compared to traditional manual systems. The journey from concept to reality in this domain involves various stages, including design, engineering, and technological integration, all aimed at meeting the growing demands of modern industry. Initially, the concept of electric hoists was born out of the need for safer and more efficient lifting solutions. Traditional lifting methods, which often relied on human strength or cumbersome mechanical systems, posed risks and inefficiencies. As the industry evolved, engineers began to explore the potential of electric power to streamline lifting operations. This exploration led to innovations in motor technology, control systems, and safety features, allowing electric hoists to lift heavier loads with greater precision and less effort.

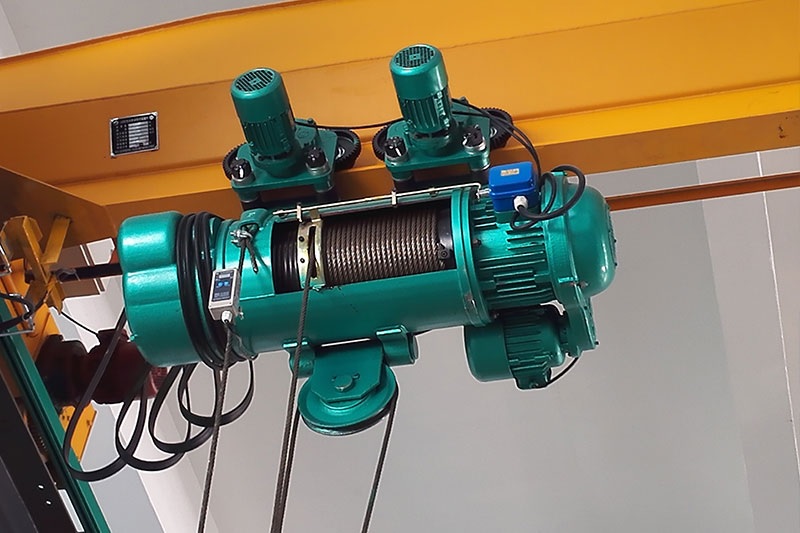

In the design phase, manufacturers focus on creating electric hoists that are not only powerful but also compact and lightweight. This is essential for crane kits, which require components that can be easily integrated without compromising the overall structure. Advanced materials, such as high-strength alloys and polymers, are often utilized to reduce weight while maintaining durability. Moreover, design engineers employ computer-aided design CAD software to model and simulate hoist performance under various conditions, ensuring that the final product can withstand the rigors of industrial use. The engineering process also involves rigorous testing and validation. Before electric hoists can be incorporated into crane kits, they undergo extensive safety testing to meet regulatory standards. This includes evaluating load limits, operational reliability, and emergency features, such as overload protection and braking systems. These tests ensure that the electric hoists can perform safely in real-world applications, minimizing the risk of accidents and injuries. Technological integration has played a pivotal role in the evolution of polipsto eléctrico de cadena within crane kits. The incorporation of smart technology has enabled features like remote control operation, real-time load monitoring, and diagnostics.

These advancements not only enhance operational efficiency but also allow for predictive maintenance, which can significantly reduce downtime and maintenance costs. Additionally, the use of wireless technology facilitates greater flexibility in operations, enabling operators to control hoists from a safe distance. Furthermore, sustainability has emerged as a critical consideration in the development of electric hoists. Manufacturers are increasingly adopting eco-friendly practices, such as using energy-efficient motors and recyclable materials. This shift not only addresses environmental concerns but also appeals to industries striving for greener operations. In conclusion, the journey from concept to reality in the manufacturing of crane kits with electric hoists involves a complex interplay of design innovation, engineering rigor, and technological advancement. These developments have revolutionized lifting operations, enhancing safety, efficiency, and sustainability in various industrial applications. As the industry continues to evolve, further innovations are expected to emerge, paving the way for even more advanced electric hoist systems in crane kits.

The mechanism by which Delta-8 THC may alleviate anxiety involves its interaction with the endocannabinoid system ECS. The ECS is a complex network of receptors and neurotransmitters in the body that helps regulate various physiological processes, including mood, stress response, and anxiety.

The mechanism by which Delta-8 THC may alleviate anxiety involves its interaction with the endocannabinoid system ECS. The ECS is a complex network of receptors and neurotransmitters in the body that helps regulate various physiological processes, including mood, stress response, and anxiety.